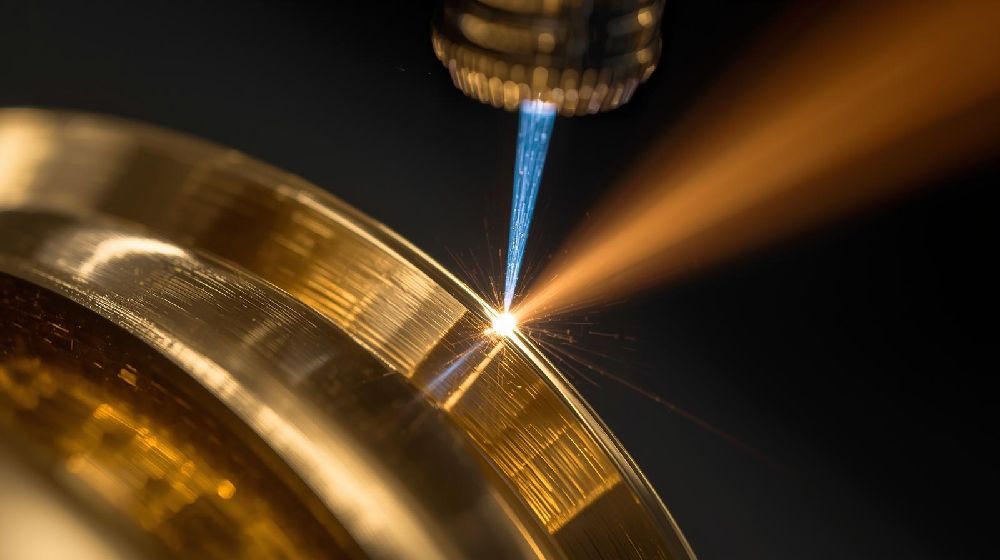

In modern gold jewelry manufacturing, precision is no longer a luxury—it's an expectation. At ORO-Z, this precision is made possible through one groundbreaking innovation: Laser Welding. As one of the most advanced technologies in fine jewelry production, laser welding enables ORO-Z to create flawless designs, stronger joints, and ultra-clean finishes that define the brand’s signature craftsmanship.

Laser welding has transformed the way gold jewelry is assembled, repaired, and perfected. With unmatched accuracy and control, it allows ORO-Z to achieve finishing standards that traditional techniques simply cannot match.

What Makes Laser Welding a Game-Changer at ORO-Z?

Laser welding uses a concentrated light beam to fuse metals together at microscopic points. Unlike soldering, it does not require melting large areas or using additional filler material. This leads to:

No visible seams or joints

Greater structural strength

Minimal heat impact on delicate designs

Highly controlled precision

For ORO-Z, this technology ensures that every piece meets the brand’s benchmark of seamless beauty.

Perfect Seamless Finish – The ORO-Z Signature

Every ORO-Z bangle, ring, and gold design goes through a finishing stage where even the smallest joint matters. Laser welding supports:

1. Invisible Joints

The welds are so fine and precise that they blend naturally into the design. This gives the jewelry a truly seamless look—one that enhances both aesthetics and durability.

2. Cleaner Edges and Smoother Surfaces

Because laser welding does not create excess solder, there are no bumps, uneven lines, or excess metal. The result is a naturally clean, smooth finish.

3. Consistent Quality Across All Designs

Whether it's CNC bangles, laser-cut patterns, double-layer assemblies, or fine detailing, laser welding ensures uniform quality across every product category.

Laser Welding in ORO-Z’s Specialized Collections

ORO-Z is known for high-precision bangles and couple bands, and many of its top-performing lines rely heavily on laser welding:

Tokyo Double Bangles

The signature overlapping structure and dual-layer technique are possible only with laser welding’s precision, ensuring perfect alignment and durability.

London Infinity & Wedding Bands

Ultra-clean, seamless edges create premium polish and enhanced comfort for daily wear.

Sydney CNC Bangles

Laser-welded joints ensure strength even in intricate designs crafted using CNC and fusion techniques.

Mumbai Lock, NY Hook & Flexible Bangles

Complex mechanisms remain secure and smooth due to micro-level welding accuracy.

Greater Strength with Minimal Heat Impact

Traditional soldering often heats large areas, risking:

Color changes

Warping

Weak joints

Detailing damage

Laser welding uses pinpoint heat, protecting:

Stones

Enamel

Filigree

CNC grooves

3D patterns

This allows ORO-Z to maintain artistic detailing without compromising durability.

Why Customers Love Laser-Welded Jewelry

Laser welding improves not only the manufacturing process but also the wearer’s experience:

Longer-lasting jewelry

Stronger joints that resist daily wear

Smooth contact surfaces—comfortable even for everyday use

Premium high-gloss finishing after polishing

It is technology that enhances beauty, performance, and value.

ORO-Z: Where Technology Meets Craftsmanship

For ORO-Z, laser welding is not a trend—it is a commitment to excellence. By integrating advanced tools with expert craftsmanship, ORO-Z consistently delivers gold jewelry that is:

Seamless

Elegant

Durable

Technically superior

Each piece is a perfect blend of innovation and artistry.

Conclusion

Laser welding has become the heart of ORO-Z’s finishing excellence. It brings unmatched precision, flawless joints, and a premium seamless look that defines the brand’s leadership in modern gold jewelry manufacturing.

At ORO-Z, laser-welded perfection isn’t just a process—it’s a promise.